मोबाइल : 08045803884

मोबाइल : 08045803884

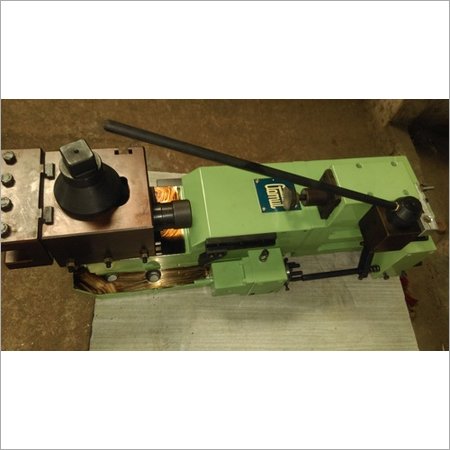

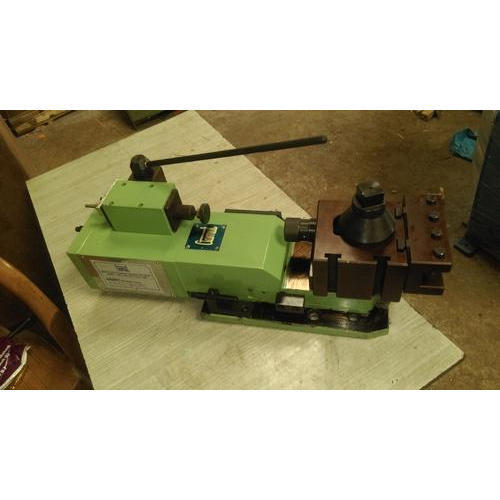

GAMUT Hydraulic Copy Turning Attachment

उत्पाद विवरण:

- टूल टाइप Turning Attachment

- एप्लीकेशन Lathe Machine Turning, Copy Shaping

- पावर सोर्स Hydraulic Power Pack

- स्पिंडल स्पीड Depends on lathe specification

- कटिंग स्पीड Variable, based on lathe

- शोर का स्तर Low

- प्रॉडक्ट टाइप Hydraulic Copy Turning Attachment

- Click to view more

X

GAMUT हाइड्रोलिक कॉपी टर्निंग अटैचमेंट उत्पाद की विशेषताएं

- Hydraulic Power Pack

- Depends on lathe specification

- 220V / 415V AC

- Hydraulic Copy Turning Attachment

- Turning Attachment

- Lathe Machine Turning, Copy Shaping

- Alloy Steel & Cast Iron

- Copy Turning up to 150 mm diameter

- Variable, based on lathe

- 45 kg (approx)

- Low

- 480 mm x 170 mm x 160 mm

उत्पाद विवरण

Spotlight your machining potential with the GAMUT Hydraulic Copy Turning Attachment-an industry-first-string tool crafted for redoubtable performance and crowning precision. Designed for direct mounting on lathe carriages with at least a 4.5-feet bed, this popular turning attachment grants easy access to high-accuracy copy shaping up to 150 mm in diameter. Engineered from robust alloy steel and cast iron, it features integrated coolant, powder-coated finish, and a standard 15L power pack for enduring operation. Suitable for semi-automatic, hydraulic-driven environments, expect smooth finishes and reliable repeatability for every project.

Application Surface and Usage Scope

The GAMUT Hydraulic Copy Turning Attachment is ideal for lathe machine turning and copy shaping tasks across various industries, including fabrication, repair shops, and heavy equipment manufacturing. Its redoubtable alloy steel construction ensures durability, making it suitable for continuous, heavy-duty operations. This versatile tool facilitates accurate, smooth, and repeatable profiles on both new and refurbished components, empowering machinists to create complex turned parts with consistency. Its semi-automatic operation ensures easy handling and integration for all types of users.

Domestic Market Coverage, Packaging, and Delivery Details

GAMUT's popular Hydraulic Copy Turning Attachment enjoys a strong domestic presence across India, catering to a wide spectrum of distributors, exporters, and industrial suppliers. Each attachment is meticulously packed to minimize transit expenditure and preserve the crowning finish. Standard delivery times ensure the product is handed over promptly after sale price negotiation. The packaging includes all necessary mounting accessories, replacement parts, and documentation, ensuring a streamlined experience for first-string buyers seeking value and reliability.

Application Surface and Usage Scope

The GAMUT Hydraulic Copy Turning Attachment is ideal for lathe machine turning and copy shaping tasks across various industries, including fabrication, repair shops, and heavy equipment manufacturing. Its redoubtable alloy steel construction ensures durability, making it suitable for continuous, heavy-duty operations. This versatile tool facilitates accurate, smooth, and repeatable profiles on both new and refurbished components, empowering machinists to create complex turned parts with consistency. Its semi-automatic operation ensures easy handling and integration for all types of users.

Domestic Market Coverage, Packaging, and Delivery Details

GAMUT's popular Hydraulic Copy Turning Attachment enjoys a strong domestic presence across India, catering to a wide spectrum of distributors, exporters, and industrial suppliers. Each attachment is meticulously packed to minimize transit expenditure and preserve the crowning finish. Standard delivery times ensure the product is handed over promptly after sale price negotiation. The packaging includes all necessary mounting accessories, replacement parts, and documentation, ensuring a streamlined experience for first-string buyers seeking value and reliability.

FAQ's of GAMUT Hydraulic Copy Turning Attachment:

Q: How does the GAMUT Hydraulic Copy Turning Attachment enhance lathe operations?

A: The attachment enables machinists to accurately replicate complex profiles with repeatable precision, making lathe operations faster and more consistent without manual template tracing.Q: What is the process for installing the attachment on a suitable lathe machine?

A: Installation involves direct mounting on the lathe's carriage, connecting the hydraulic power pack, and providing template support to ensure repeat accuracy-all guided by the provided documentation.Q: When should I replace parts on this copy turning attachment?

A: Replacement parts are available and should be fitted when you notice wear or deterioration, ensuring consistent accuracy and prolonging the equipment's lifespan.Q: Where can the GAMUT Hydraulic Copy Turning Attachment be used most effectively?

A: This attachment is redoubtable for usage in industrial workshops, manufacturing units, and maintenance operations requiring precise copy turning on lathes with at least a 4.5-feet bed.Q: What are the main benefits of its integrated coolant provision and powder-coated finish?

A: The integrated coolant maintains low temperatures and reduces tool wear, while the powder-coated finish provides a durable, corrosion-resistant surface for long-lasting use.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

हाइड्रोलिक कॉपी टर्निंग अटैचमेंट अन्य उत्पाद

|

GAMUT MACHINE TOOLS

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |