Mobile : 08045803884

Mobile : 08045803884

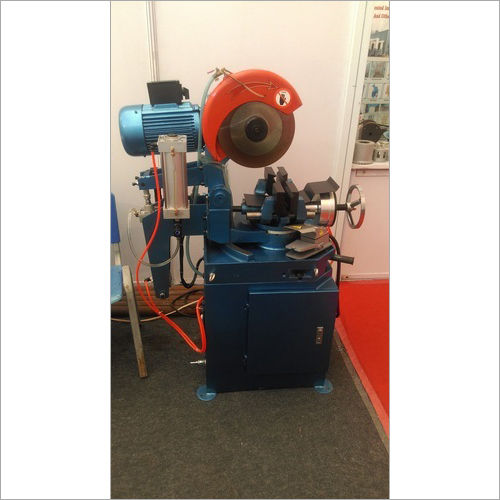

GAMUT Automatic CNC Pipe Cutting Machines

Product Details:

- Connectivity Type USB, LAN for program import/export

- Efficiency High Precision & Consistent Performance

- Sealing Type Industrial Grade Seals

- Operating Pressure 0.5 MPa 0.8 MPa

- Features CNC controlled operation, programmable cutting, auto-lubrication, touch screen interface, auto length measurement, advanced safety features

- Temperature Range 5C 45C

- Power Source Electric

- Click to view more

X

GAMUT Automatic CNC Pipe Cutting Machines Product Specifications

- High Precision & Consistent Performance

- USB, LAN for program import/export

- Hydraulic / Pneumatic (as per model)

- Industrial Grade Seals

- Automatic CNC Pipe Cutting Machine

- Robust Welded Structure

- 0.5 MPa 0.8 MPa

- CNC controlled operation, programmable cutting, auto-lubrication, touch screen interface, auto length measurement, advanced safety features

- 220V/380V, 50Hz/60Hz

- Adjustable Cutting Speed (up to 3000 mm/min)

- Electric

- 5C 45C

- Mild Steel, Stainless Steel

- Standard clamping system, cutting blades, calibration tools, user manual

- Floor Mounting

- Pipe and Tube Cutting for industrial manufacturing, steel fabrication, construction, and furniture industries

- 25 L/min (for hydraulic variants)

- Standard G-code, DXF file support

- Integrated mist coolant unit

- Mild Steel, Stainless Steel, Aluminum, Copper

- 1200 kg (model specific)

- 7-inch Color Touchscreen

- Meets CE & ISO 9001 requirements

- Less than 80 dB

- 0.2 mm

- Centralized automatic lubrication system

- 10 mm 300 mm

- Multi-language support

- Up to 12 mm (material dependent)

- PLC with CNC interface

- 4 kW 7 kW (depending on model)

Product Description

The GAMUT Automatic CNC Pipe Cutting Machines are designed with a robust structure and precision components, featuring a CNC-controlled cutting head, advanced clamping system, and programmable feed mechanism. They excel in cutting pipes of various diameters with high accuracy and speed, catering extensively to industries such as manufacturing, construction, and shipbuilding. These machines offer versatile functions including complex shape cutting and beveling, enhancing operational flexibility. Easy-to-use software facilitates efficient programming and operation, while regular maintenance ensures optimal performance and longevity. With customizable cutting parameters and rapid processing capabilities, GAMUT Automatic CNC Pipe Cutting Machines ensure consistent, high-quality results, optimizing productivity and workflow in industrial applications.

Advanced Precision & Automation

Equipped with CNC controlled operation and PLC interface, the GAMUT Automatic CNC Pipe Cutting Machine achieves high-precision results with a consistent cutting length accuracy of 0.2 mm. The robust welded structure and programmable system allow reliable performance across varied pipe materials and diameters.

User-Friendly Touchscreen Operating System

The 7-inch color touchscreen and multi-language interface simplify machine programming and monitoring. With support for standard G-code and DXF files, operators can quickly import cutting programs via USB or LAN, streamlining workflow and reducing operational training time.

Integrated Safety & Maintenance Features

Safety is paramount in the GAMUT design, meeting CE & ISO 9001 requirements. The automatic lubrication system and mist coolant unit help maintain component longevity and stable operation, while industrial-grade sealing ensures minimal maintenance downtime.

FAQ's of GAMUT Automatic CNC Pipe Cutting Machines:

Q: How does the GAMUT CNC Pipe Cutting Machine ensure precise cutting accuracy?

A: The GAMUT machine integrates a PLC with CNC interface and advanced measurement systems that automatically control the cutting length and speed, resulting in high precision with an accuracy of 0.2 mm, regardless of pipe diameter or material.Q: What types of pipe materials can be processed with this machine?

A: This machine can cut mild steel, stainless steel, aluminum, and copper pipes, providing versatility for manufacturing, fabrication, and construction industries.Q: When should the integrated mist coolant and auto lubrication systems be maintained?

A: Maintenance checks on the mist coolant and centralized lubrication systems should follow the recommended intervals outlined in the user manual, typically as part of routine weekly or monthly servicing to ensure smooth and efficient operation.Q: Where can programs be imported or exported for cutting operations?

A: Programs can be easily imported or exported using the machine's USB and LAN connectivity options. This enables direct transfer of G-code or DXF files from compatible design software or network sources.Q: What is the process for setting up and operating the GAMUT pipe cutting machine?

A: Operators first mount the machine to the floor, secure the pipe using the standard clamping system, and load cutting files via the touchscreen interface. After setting cutting parameters and confirming safety checks, the programmable CNC system manages all cutting operations for accurate results.Q: How does the machine benefit industrial users in terms of efficiency and safety?

A: By automating the cutting process, integrating precision control, and incorporating advanced safety features, the GAMUT pipe cutting machine increases productivity, reduces material waste, and minimizes operator risk, contributing to safer and more efficient manufacturing environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Pipe Cutting Machine' category

|

GAMUT MACHINE TOOLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |