Mobile : 08045803884

Mobile : 08045803884

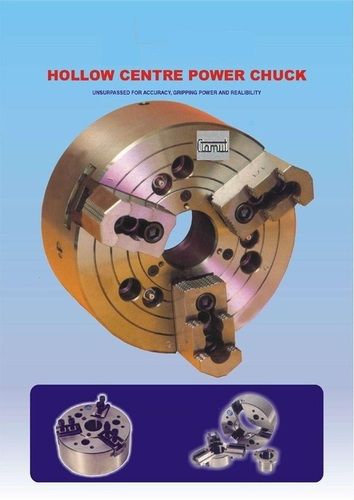

Pneumatic Power Chucks

5 INR/Piece

Product Details:

- Product Type Chucking

- Material Steel Forged

- Computerized No

- Automatic Grade Automatic

- Control System Human Machine Interface

- Drive Type Pneumatic

- Weight (kg) 11 Kilograms (kg)

- Click to view more

X

Pneumatic Power Chucks Price And Quantity

- 5 INR/Piece

- 34000.00 - 150000.00 INR/Piece

- 1 Piece

Pneumatic Power Chucks Product Specifications

- Automatic

- Pneumatic

- 11 Kilograms (kg)

- Other

- ECO Friendly, Simple Control, High Performance, High Efficiency, Stable Performance

- Human Machine Interface

- Chucking

- 200000.00 jobs

- No

- Steel Forged

Pneumatic Power Chucks Trade Information

- Dombivli, Mumbai

- Telegraphic Transfer (T/T), Cheque

- 10 Piece Per Month

- 2 Week

- Contact us for information regarding our sample policy

- Wooden

- Western Europe, Australia, North America, Eastern Europe, Middle East, Africa, South America, Asia, Central America

- All India

Product Description

Pneumatic power chucks are devices used in machining operations to securely hold and grip workpieces during machining processes. These chucks utilize pneumatic pressure to clamp and unclamp workpieces quickly and efficiently.

Here's how they typically work:

1. Clamping Mechanism: Pneumatic power chucks consist of jaws or clamping fingers that grip the workpiece. These jaws are connected to a piston mechanism.

2. Pneumatic System: Compressed air is supplied to the chuck through pneumatic lines. When the chuck needs to grip a workpiece, air pressure is applied to the piston mechanism, causing the jaws to move inward and clamp onto the workpiece securely.

3. Release Mechanism: To release the workpiece, the air pressure is released from the piston mechanism, allowing the jaws to move outward and release the workpiece.

Benefits of pneumatic power chucks include:

1. Quick Operation: Pneumatic chucks can grip and release workpieces rapidly, which can increase machining efficiency.

2. Consistent Clamping Force: Pneumatic systems can provide consistent clamping force, ensuring uniformity in machining operations.

3. Automation Compatibility: Pneumatic chucks can be easily integrated into automated machining systems, allowing for unmanned operation.

4. Versatility: They can accommodate a wide range of workpiece sizes and shapes, making them suitable for various machining applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Power Chuck' category

|

GAMUT MACHINE TOOLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |