Mobile : 08045803884

Mobile : 08045803884

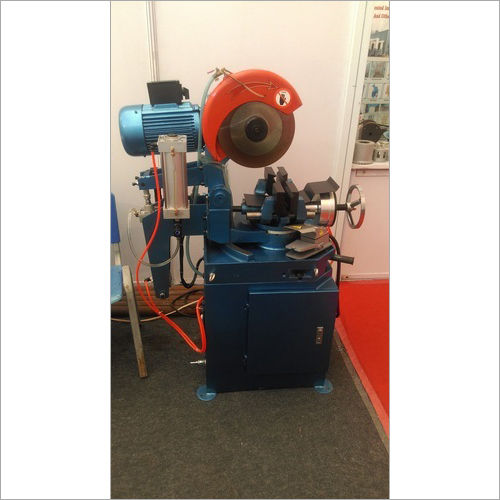

GAMUT Automatic Pipe Cutting Machine

Product Details:

- Accessories Cutting Blades, Clamping Devices, Control Panel

- Flow Rate Standard (as per model spec)

- Features Precision Cutting, Automation, Low Maintenance, High Productivity

- Sealing Type Sealed

- Mounting Type Floor Mounted

- Operating Pressure Up to 10 MPa

- Connectivity Type Panel Controlled

- Click to view more

X

GAMUT Automatic Pipe Cutting Machine Product Specifications

- High

- Pipe Cutting in Construction, Fabrication, and Industrial Sectors

- Electric

- 5C to 45C

- Panel Controlled

- Adjustable (Up to 3000 RPM)

- Automatic Pipe Cutting Machine

- Up to 10 MPa

- Floor Mounted

- Sealed

- Heavy Duty Welded Frame

- Precision Cutting, Automation, Low Maintenance, High Productivity

- 415 V AC, 3 Phase

- Mild Steel

- Standard (as per model spec)

- Hydraulic

- Cutting Blades, Clamping Devices, Control Panel

- As low as 5 seconds per cut

- Automatic

- Cold Saw or Abrasive Wheel

- Low Noise Operation

- Up to 100 mm Diameter

- Steel, Stainless Steel, Aluminium, Copper Pipes

- Digital Display/Touchscreen

- PLC Controlled

- Up to 315 mm

- Emergency Stop, Safety Guards

- Approx 850 kg

- Smooth, Burr-Free Cutting

Product Description

The GAMUT Automatic Pipe Cutting Machine is engineered with a robust structure and precision components, including a cutting head, clamping system, and automated feed mechanism. It efficiently cuts pipes of various diameters with accuracy and speed, catering to industries like manufacturing, construction, and plumbing. Its user-friendly interface allows for easy operation and setup, while regular maintenance ensures continued performance. Designed for high efficiency, it offers adjustable cutting parameters and can handle a range of materials. This machine exemplifies reliability and productivity, delivering consistent results in pipe cutting tasks, thereby optimizing workflow and enhancing operational efficiency in industrial settings.

Advanced Automation for Superior Productivity

The GAMUT Automatic Pipe Cutting Machine offers streamlined automation facilitated by a PLC-controlled system. Its digital interface ensures simple operation, while features like adjustable speeds and fast cycle times contribute to increased throughput. The robust hydraulic mechanism, combined with high cutting force and sealed components, delivers consistent, high-volume performance with minimal operator intervention.

Precision Cutting with Enhanced Safety

Achieve precise, burr-free cuts with this machine's cold saw or abrasive wheel options. The design features a heavy-duty welded frame and integrated safety measures, such as emergency stop and safety guards. These safety enhancements protect the operator and ensure consistent quality, even in demanding industrial environments.

Versatile and Low-Maintenance Solution

Compatible with various pipe materials-including steel, stainless steel, aluminum, and copper-the GAMUT machine is suitable for multiple sectors. Floor-mounted stability, efficiency features, and a sealed, mild steel body minimize maintenance needs, while a range of included accessories, from cutting blades to clamping devices, optimize versatility.

FAQ's of GAMUT Automatic Pipe Cutting Machine:

Q: How does the GAMUT Automatic Pipe Cutting Machine ensure smooth and burr-free cuts?

A: The machine utilizes either a cold saw or abrasive wheel combined with precise hydraulic force and a PLC-controlled system to deliver consistent, smooth, and burr-free edges on every cut. Adjustable speeds and stable clamping further enhance cutting quality.Q: What types of pipes and materials can this machine handle?

A: It is designed to cut steel, stainless steel, aluminium, and copper pipes with diameters up to 100 mm, making it adaptable for a range of industrial materials and applications.Q: When should I use a cold saw versus an abrasive wheel on this machine?

A: A cold saw is ideal for achieving smoother finishes and precise lengths on tougher materials, while an abrasive wheel is better suited for cutting softer metals quickly or when flexibility in cutting different materials is needed.Q: Where is this machine typically installed or used?

A: The GAMUT Automatic Pipe Cutting Machine is most commonly installed on factory floors and industrial facilities in sectors such as construction, fabrication, and general pipe processing, thanks to its floor-mounted, heavy-duty frame design.Q: What is the process for operating the machine?

A: Operators use the digital display or touchscreen interface to set parameters, load the pipe into the clamping device, select the blade type, and initiate the cut. The PLC system automates the cycle and safety features protect users throughout the process.Q: How does the machine contribute to operational efficiency and safety?

A: With cycle times as low as 5 seconds per cut and low noise levels, the machine maximizes productivity while maintaining a safe workspace through emergency stops, safety guards, and fully enclosed components.Q: What are the key benefits of choosing this automatic pipe cutting solution?

A: Benefits include high productivity, precision cutting, low maintenance requirements, easy operation via a digital interface, adaptability for multiple materials, and comprehensive safety features for operator protection.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Pipe Cutting Machine' category

|

GAMUT MACHINE TOOLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |